|

|

|

Lost

Wax Investment Casting commences with the production

of High Quality Wax Patterns from Aluminum Injection

Tooling. These are then mounted onto a wax runner

system and the assembly is coated several times

with ceramic material and air-dried. |

|

On

completion, the mould is de-waxed leaving an empty

shell which is subsequently fired and filled with

molten metal. The shell is then allowed to cool

and removed.

Castings are cut from the runner system, finished,

heat treated (when required), straightened, sand

blasted and passed through to quality control

for a rigid inspection program.

This process uses only the finest quality raw

material to create fine tolerances, good surface

finishes and repeatable castings in a wide range

of cast materials sizes and shapes.

|

|

|

|

|

| |

|

|

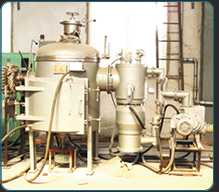

We are

using the most advanced Vacuum Induction Melting

technology(VIM) for the Refining of high purity

metal and alloys. Such as Nickel based Alloys and

Cobalt based alloys. As known as the famous Haynes

alloys

|

| Parameter |

Unit |

|

|

Capacity (Measure by steel

) |

Kg |

25 |

|

Highest Working Temp. |

C |

1700 |

|

Rated intermediate Frequency

Power |

kW |

100 |

|

Rated Intermediate Frequency |

Hz |

2500 |

|

Rated Voltage |

V |

250 |

|

Limit vacuum of the Equipment |

Pa |

6.67*10-3 |

|

Pressure Rise Rate |

Pa/h |

6.5 |

|

Cooling Water Consumption

Rate |

L/min |

100 |

|

|

|

|

|

|